Comprehensive Guide To Toothpaste Production: Ingredients, Processes, Quality, And Sustainability

Toothpaste production involves manufacturers, who leverage essential ingredients such as fluoride, abrasives, and humectants. Through intricate processes employing advanced equipment, these ingredients are blended, mixed, and shaped into the final product. Quality control measures ensure product consistency and safety, while environmental considerations guide sustainable practices.

Manufacturers: The Pillars of the Industry

The world of manufacturing is a complex and fascinating one, filled with industry giants that shape the products we use every day. Leading manufacturers are not just producers of goods; they are innovators, pioneers, and visionaries who drive technological advancements and set industry standards.

In this blog post, we'll delve into the key players of the manufacturing industry, exploring their market dominance, groundbreaking innovations, and the diverse product portfolios that make them household names.

Market Dominance: Commanding the Landscape

Leading manufacturers wield significant market share, dominating their respective sectors with strong brand recognition and a loyal customer base. These companies have established a robust presence across global markets, catering to the needs of consumers on a vast scale. Their ability to scale production and optimize supply chains ensures a constant flow of high-quality products to meet market demand.

Innovation: Fueling Progress

Innovation is the lifeblood of the manufacturing industry, and leading manufacturers are at the forefront of technological advancements. They invest heavily in research and development (R&D), perpetually pushing the boundaries of possibility. Their groundbreaking innovations have revolutionized the way products are made, improving efficiency, enhancing functionality, and creating entirely new categories of products.

Product Offerings: A Symphony of Choices

Leading manufacturers offer a diverse range of products, catering to the unique needs of consumers across various segments. From household appliances to cutting-edge electronics, these companies have mastered the art of creating products that solve problems, enhance experiences, and fulfill aspirations. Their comprehensive portfolios include a wide array of options, providing consumers with ample choice and customization potential.

In conclusion, leading manufacturers are the cornerstones of the manufacturing industry. They dominate markets, drive innovation, and offer exceptional product offerings that shape the way we live. Their commitment to quality, technological advancements, and customer satisfaction has made them trusted partners in our daily lives.

Essential Ingredients: The Building Blocks of Products

In the realm of manufacturing, the choice of ingredients is paramount. These are the raw materials that shape the final products, dictating their functionality, safety, and appeal. Understanding the essential ingredients used in the manufacturing process is crucial for customers and enthusiasts alike.

Primary Ingredients: A Foundation of Performance

The foundation of any product lies in its primary ingredients. These materials determine the product's core characteristics, such as strength, durability, and appearance. In the automotive industry, for instance, steel is the primary ingredient for car bodies due to its strength-to-weight ratio. In the electronics industry, silicon is the key component in semiconductors, enabling the powerful microchips that drive our devices.

Importance and Functionality: Beyond the Surface

Beyond their physical properties, essential ingredients also play specific functional roles. Take the example of concrete, where cement, sand, and gravel come together to form a durable building material. Cement acts as the binder, sand provides strength, and gravel reduces shrinkage and cracking. Similarly, in the food industry, sugar and flour are essential ingredients in baked goods, providing sweetness and structure respectively.

Sourcing: Traceability and Quality Assurance

The sourcing of essential ingredients is critical for maintaining product quality and safety. Manufacturers must ensure that their ingredients meet specific standards and are ethically sourced. This involves tracing the origin of materials, verifying supplier certifications, and adhering to regulatory requirements. By doing so, manufacturers can guarantee the reliability and safety of their products.

Essential ingredients are the lifeblood of the manufacturing industry. They dictate the performance, functionality, and safety of products. Understanding these ingredients empowers consumers to make informed decisions about the products they purchase. For manufacturers, the careful selection and sourcing of essential ingredients is a testament to their commitment to quality and innovation. As technology continues to advance, manufacturers will continue to explore new and improved ingredients to create products that enhance our lives.

Intricate Processes: Unveiling the Production Secrets

In the realm of manufacturing, where innovation thrives and quality reigns supreme, intricate processes play a pivotal role in transforming raw materials into exceptional products. Dive into the heart of these production secrets and witness the meticulous craftsmanship that lies behind every masterpiece.

Unveiling the Key Production Stages

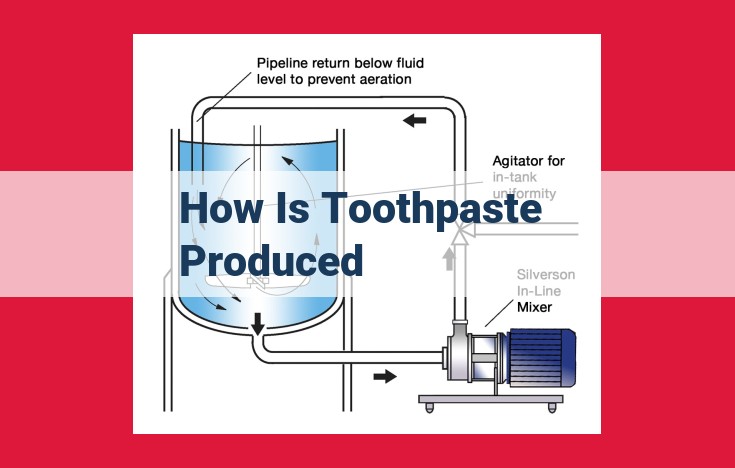

The journey of raw materials to finished products unfolds through a series of precisely orchestrated production stages. Blending, mixing, and compounding meticulously combine ingredients to achieve the desired consistency, texture, and functionality. Molding and shaping techniques, ranging from injection molding to extrusion, give form to the products, ensuring their structural integrity and aesthetics.

Embracing Technological Advancements

Technology has become an indispensable ally in the manufacturing process. Computer-aided design (CAD) software empowers designers to create precise digital models, minimizing errors and optimizing production efficiency. _Automated machinery performs repetitive tasks with unwavering accuracy, increasing productivity and ensuring consistent quality. _Advanced monitoring systems vigilantly track production parameters, enabling real-time adjustments and preventing defects.

Implementing Rigorous Quality Control

Quality is the cornerstone of manufacturing excellence. Meticulous inspections at every stage ensure that products meet exacting standards. _Statistical process control (SPC) techniques identify and eliminate variations, guaranteeing product consistency. _Third-party certifications provide independent verification of quality, giving customers peace of mind.

Mindful of Environmental Responsibility

Modern manufacturing practices embrace sustainability. _Environmentally friendly materials reduce the ecological footprint of products. _Energy-efficient processes minimize energy consumption and carbon emissions. _Waste management programs ensure responsible disposal of byproducts, fostering a harmonious relationship with the planet.

Intricate processes are the backbone of manufacturing, transforming raw materials into products that enhance our lives. By embracing technological advancements, implementing rigorous quality control measures, and prioritizing environmental responsibility, manufacturers craft products of exceptional quality that meet the evolving needs of today's discerning consumers.

Specialized Equipment: Empowering Innovation in the Industry

In the realm of manufacturing, specialized equipment plays a pivotal role in driving innovation and enhancing production efficiency. From state-of-the-art machinery to precision instruments, these technological marvels empower manufacturers to craft exceptional products, optimize processes, and cater to evolving market demands.

One such essential piece of equipment is the Computer Numerical Control (CNC) machine. This high-precision tool harnesses computer-aided design (CAD) software to guide cutting tools, enabling manufacturers to produce intricate parts with unparalleled accuracy and repeatability. Its automated operation minimizes human error, ensuring consistent quality and reducing production time.

Another indispensable tool is the 3D printer. This revolutionary technology enables rapid prototyping and small-batch production. By layering materials in a controlled manner, 3D printers create complex geometries and customized components with remarkable detail. Their versatility empowers manufacturers to explore innovative designs, test prototypes, and bring products to market faster.

Furthermore, automated assembly lines streamline the production process by integrating multiple machines and workstations. These systems leverage programmable logic controllers (PLCs) to coordinate the movement of parts and materials, ensuring a seamless and efficient flow of production. Automated assembly lines enhance productivity, reduce labor costs, and improve overall production quality.

In the realm of quality control, optical inspection systems play a crucial role. These advanced devices employ high-resolution cameras and lighting to detect even the smallest defects and imperfections in products. Their ability to analyze large volumes of data at high speeds ensures that only the highest quality products reach the market.

Lastly, environmental monitoring equipment is critical for maintaining optimal production conditions. Sensors and monitors track temperature, humidity, and other environmental factors that can impact product quality. Real-time data collection enables manufacturers to make proactive adjustments, minimizing production downtime and ensuring a safe and healthy work environment.

By harnessing the power of specialized equipment, manufacturers can unlock new levels of innovation, efficiency, and quality. These technological marvels empower them to meet the evolving demands of the industry, satisfy customer expectations, and drive the future of manufacturing excellence.

Related Topics:

- How To Say “Wash” In Spanish: A Comprehensive Guide To “Lavar” And “Lavarse”

- Master The Pronunciation Of “Manipulated” With Step-By-Step Instructions

- How To Pronounce “Gerbera”: A Comprehensive Guide With Syllable-By-Syllable Breakdown

- Unveiling Globetrotters’ Salary Dynamics: A Comprehensive Guide

- Mastering “Buoyant” Pronunciation: Expert Guide For Crystal-Clear Speech